Agricultural Industry

Sistema de Qualidade

-

ISO 9001:2015 / JISQ9001:2015

Qualidade Certificada

-

ISO 14001:2015

Sistema de Gestão Ambiental Certificada

-

ISO 45001:2018

Sistemas de Gestão de Saúde e Segurança Ocupacional

-

ISO/IEC 17025:2017 (LAB TAF)

Sistema de Qualidade Certificada Aprovada Por Laboratório Interno com Equipamento Integrado

-

RoHS Compliant

We do not intentionally use any hazardous material required by “RoHS2 EU Directive 2011/65/EU and RoHS3 EU Directive EU/ 2015/863” within compounding process and any others processes.

-

REACH Compliant

We hereby declare that all products(articles) have been designed and manufactured do not contain SVHC above the threshold value.

Download do Catálogo

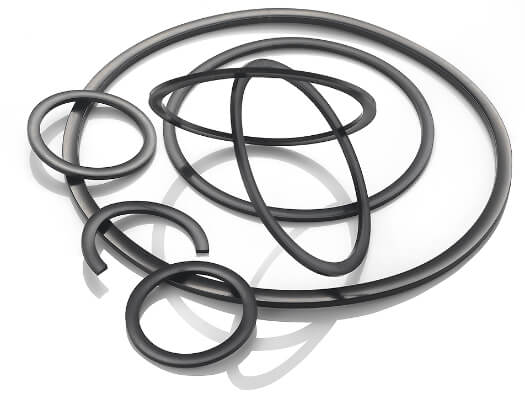

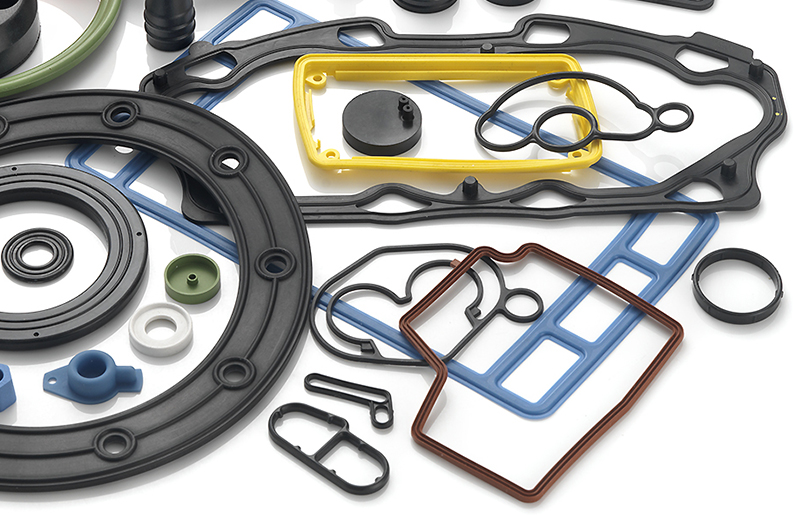

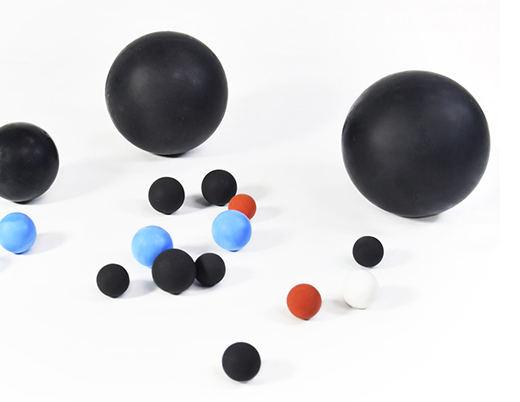

Industrial agricultural processes uses different tools and mechanical equipment at every stage of production from crop cultivation and harvesting to packaging and transportation. The rubber sealing components used in these equipment come into contact with various agrochemicals and are also exposed to weathering and UV Degradation.

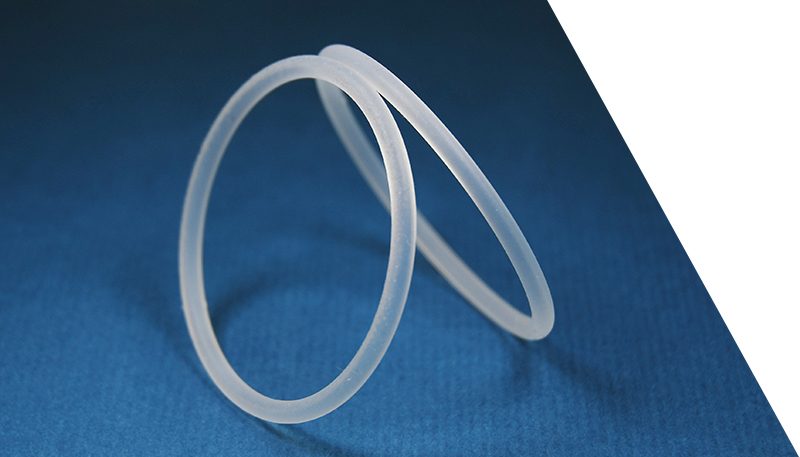

GMORS has developed material formulations such as FKM, NBR, HNBR, VMQ and EPDM that meet the specifications of world-renowned agricultural multinational companies. Long-term compression set tests exceeding 1,000 hours are conducted to ensure that sealing performance is up to expectations. GMORS offers technical advice and recommendations for material selection based upon working conditions such as exposure to ozone degradation, refrigerant, motor oil, coolant, urea, plant nutrients, liquid fertilizer, herbicide, fungicide and pesticides. Material compatibility will determine volume swell or shrinkage as well as the behavior of the elastomer under exposure to certain corrosive chemicals. This will prevent premature seal failure and extend the service life expectancy of the sealing product.

GMORS design engineers assists customers with material recommendations, improving the quality of designs and reducing the need for recalls or parts replacement.

Over the past few decades, GMORS has maintained a dedicated R&D team and established TAF / ISO 17025 certified laboratory, providing customized product designs and material R&D services to meet the special requirements of our customers. We continue to improve our manufacturing capabilities and quality system management. Our investment in the systematic management of manufacturing processes and logistics enables the effective traceability of every production batch whenever necessary.